TWIN Conveyor Monitoring System

The TWIN Conveyor Monitoring System is our patented solution to monitor and predict the failure of roller bearings. It is optimized for medium- and heavy-duty conveyors with lengths of up to several kilometers.

Key Features

Vibration – Noise – Heat

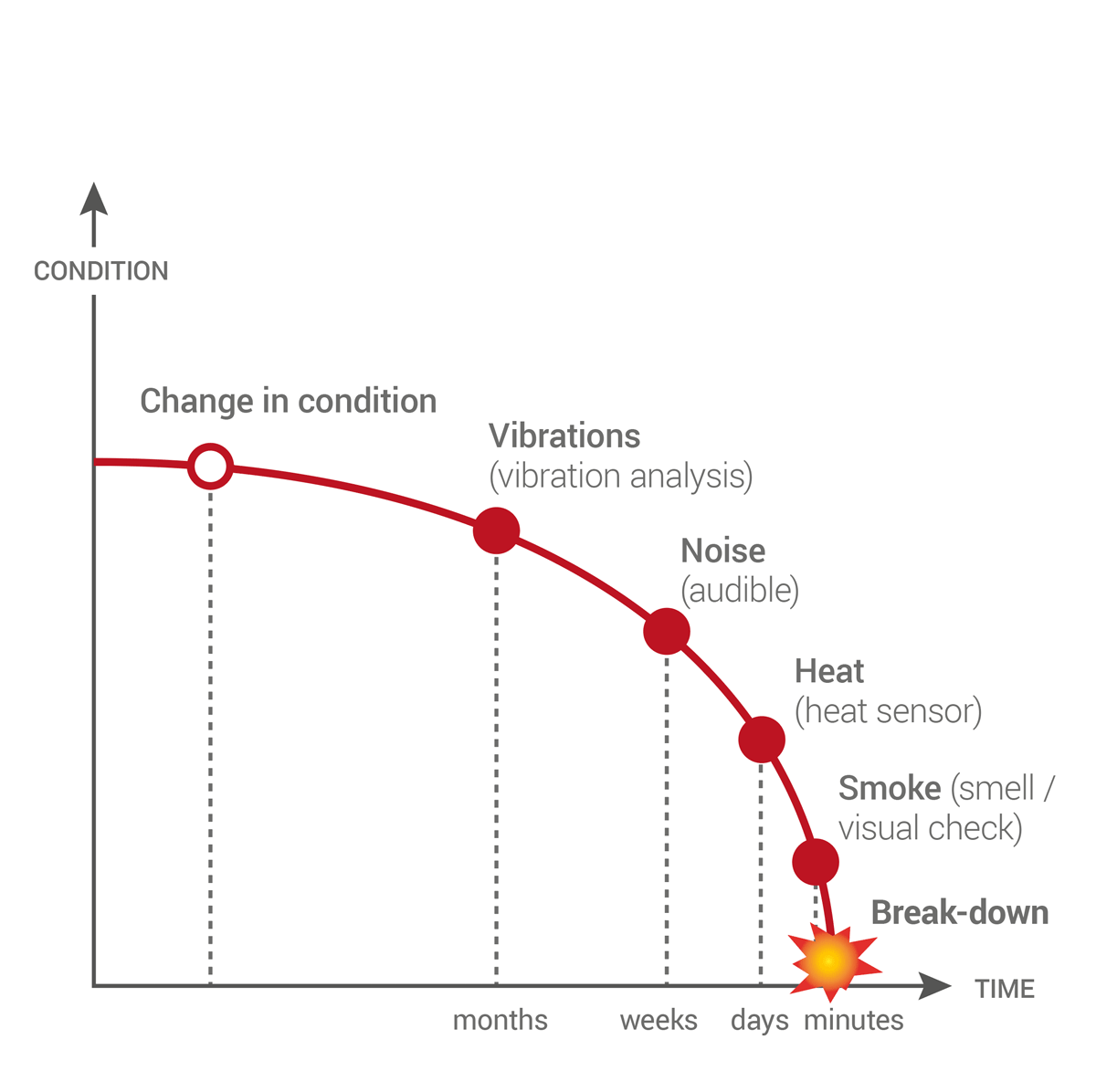

Typically, when a roller starts to fail it is going to deteriorate over months until it finally breaks.

Vibration occurs months to weeks before a roller bearing breaks, audible noises occur weeks to days before, and heat only days before the failure. This is why TWIN monitors vibration. No other approach allows to detect impending failures earlier.

The cost to repair increases drastically the later a failure is detected. Unplanned down-times may be extremely costly, e.g. in coal-mines EUR 100,000+ per hour.

Makes your job easier & saves you money

TWIN at a glance:

- Prevents damages to the belt.

- Enables predictive maintenance.

- Reduces unplanned down-times.

- Pinpoints the exact location of the failing roller.

- Easily interfaces with existing monitoring and control platforms and SCADA systems.

Optionally the TWIN Conveyor Monitoring System maybe upgraded with temperature sensors which adds a fire-detection function to the system.

The TWIN Conveyor Monitoring System is the unparalleled solution to monitor conveyor rollers.